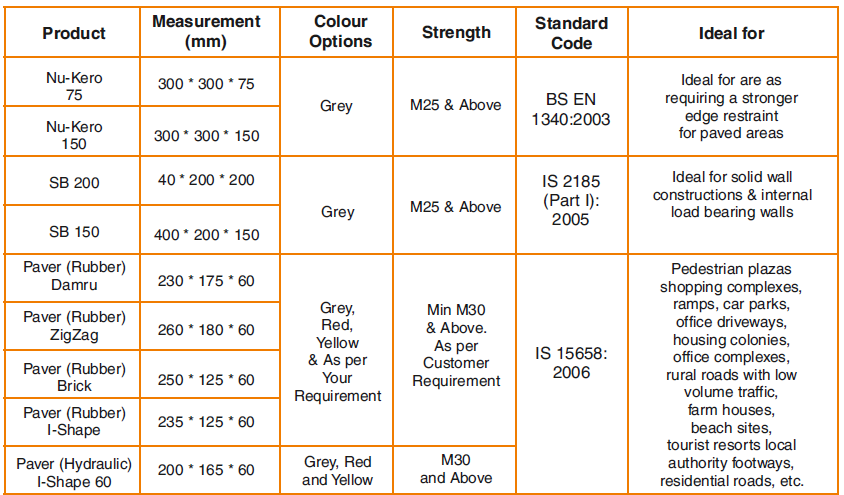

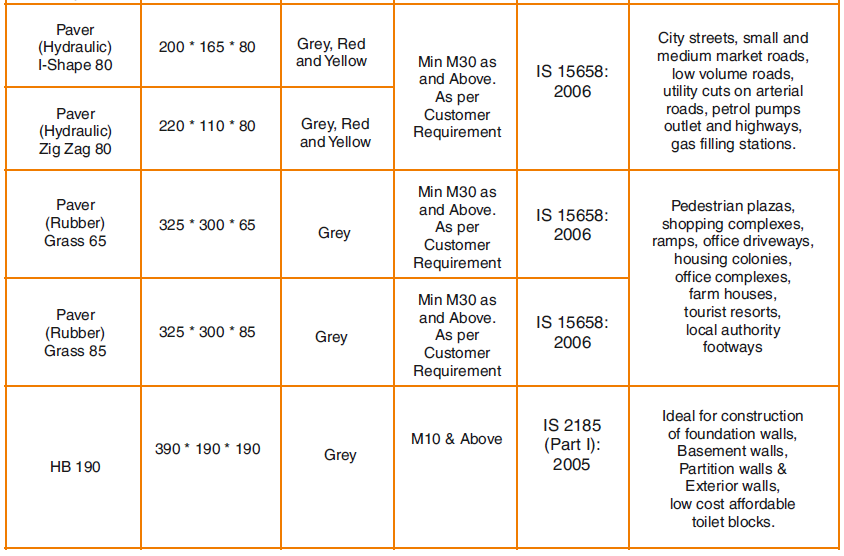

Products

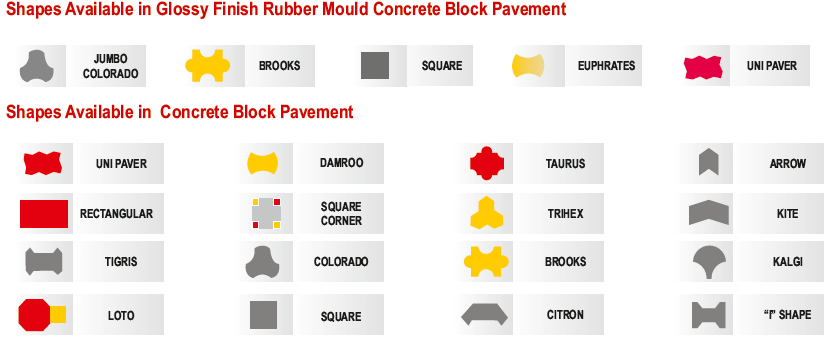

Concrete Block Pavement

An Environment Friendly Technique

Concrete Pavers act as a zipper in the pavement. When the need arises to make underground repair, interlocking concrete pavement can be removed and replaced using the same materials. Unlike asphalt or poured-in-place concrete, paving blocks can be opened and closed without jack hammers and with less construction equipment. The process of reusing the same paving units is called reinstatement.

Advantages of Concrete Block Pavement

– No need for heavy construction equipment

– Factory production facilitates centralized quality control

– Labour intensive construction

– Instant opening to traffic

– No thermal expansion and contraction of concrete

– Accommodates higher elastic deflection without failure

– Pavement not damaged due to fuel and oil spillage

– High salvage value – almost all blocks can be recycled / reused

– Least life cycle cost due to low maintenance cost

– Environment friendly technology.

Areas where ICBP is successfully proven are:

Parking areas, footpaths, non-trafficked areas, low traffic intensity streets, petrol pumps, office and residential complexes and light to medium trafficked areas etc.

General Specification :

50 mm thick paver made of M-250 grade concrete

recommended for light load.

60 & 80 mm thick paver made of M-250, 350 & 400 grade

recommended for heavy commercial use.

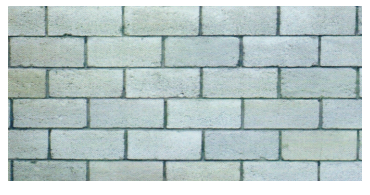

Fly Ash Bricks

Ash bricks are made of

Fly ash, lime, gypsum and coarse sand.

Features

Durable, low water absorption, Economical & eco-friendly, Low energy consumption, No emission of green house gases, Ash content up to 60 % by weight of brick, Lighter in weight than conventional clay bricks

Compressive strength , more than 100kg/sq.cm ., Uniform in shape with

frog, more durable as strength increases with passage of time, water

absorption within permissible limits, Less mortar consumption in masonry, Savings in construction cost, Cost is comparable with conventional bricks.

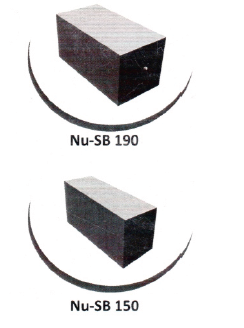

Nuearth Masonary Product

- Size Available 400 x 200 x 150 MM & 400 x 200 x 200 MM

- Compressive strength more than 5 N/Mm2 (As per IS 2185 Part 2)

- Size tolerance 1.5 mm (+/-)

Concrete Bricks

- Density 2100 Kg/CMT

- Efforescence – N/A

- Curing – require less water during masonry

- Usage – Compound wall & Building masonry work

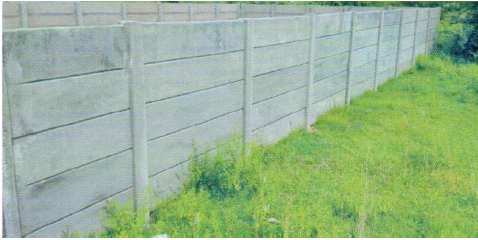

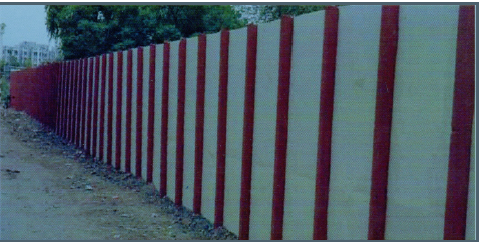

Wall Compound

Leveraging on our vast manufacturing facilities, we are able to offer our client with Compound wall for Building Construction that widely finds application in various corporate houses, residential houses and industries

Another Variety

- Size 1990 x 2100 x 50 mm

- Column Size 150 x 150 x 2600 mm

- We use PCC Still with 3 x 3 mm and per beams

- 4 pieces, with stressing system

One More

Offering our client with Compound wall for Building Construction that widely finds application in various corporate houses, residential houses and industries.